Micro Arc Welding provides advanced precision micro laser & TIG welding solutions, machining, fabrication & supply chain management across all industries

NADCAP & ITAR Certified Welding for Aerospace, Medical, Defense, Manufacturing, and Oil & Gas Industries

Anchored in decades of experience and expertise, Micro Arc Welding provides advanced precision micro laser & TIG welding solutions, machining, fabrication & supply chain management across all industries

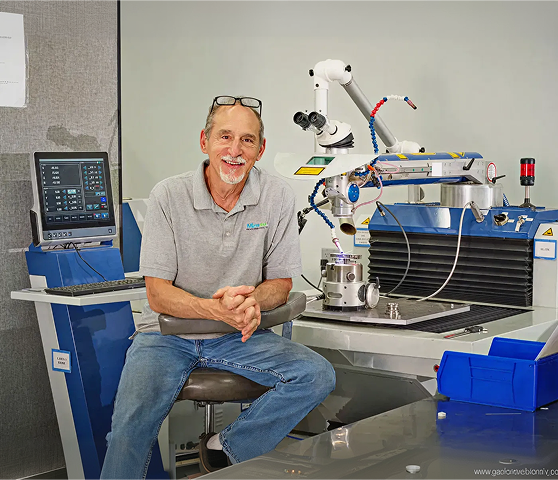

Micro Arc Welding has been a trusted leader in micro-scale welding for over 40 years, making us one of the oldest and most experienced specialized micro welding shops in the United States.

We fill a unique niche in the manufacturing supply chain — handling precision welding tasks that automated systems and traditional welders simply can’t execute. Using advanced laser and TIG welding, along with spot welding techniques, we work one-on-one with clients, providing personal attention, direct communication with our welders and managers, and solutions tailored to each project.

Founded by welding expert Scott Malkasian, who developed his skill from the ground up in tool, die, and moldmaking environments, Micro Arc combines hands-on craftsmanship with deep industrial knowledge. Scott’s early experiences and dedication to quality have shaped a company that doesn’t just weld parts.

Micro Arc’s capability has made us a valued partner for diverse clients — from local businesses to global leaders — in industries where precision, reliability, and critical performance are essential

We support manufacturers across highly regulated and precision-driven industries. Whether it’s a critical aerospace project, a national defense component, a complex prototype, large scale production parts, even the onesie, twosie parts that others won’t touch, with our advanced welding expertise, unapparelled precision, and state of the art equipment, Micro Arc ensures the highest quality results every time.

Nadcap-accredited welding for mission-critical and non critical parts.

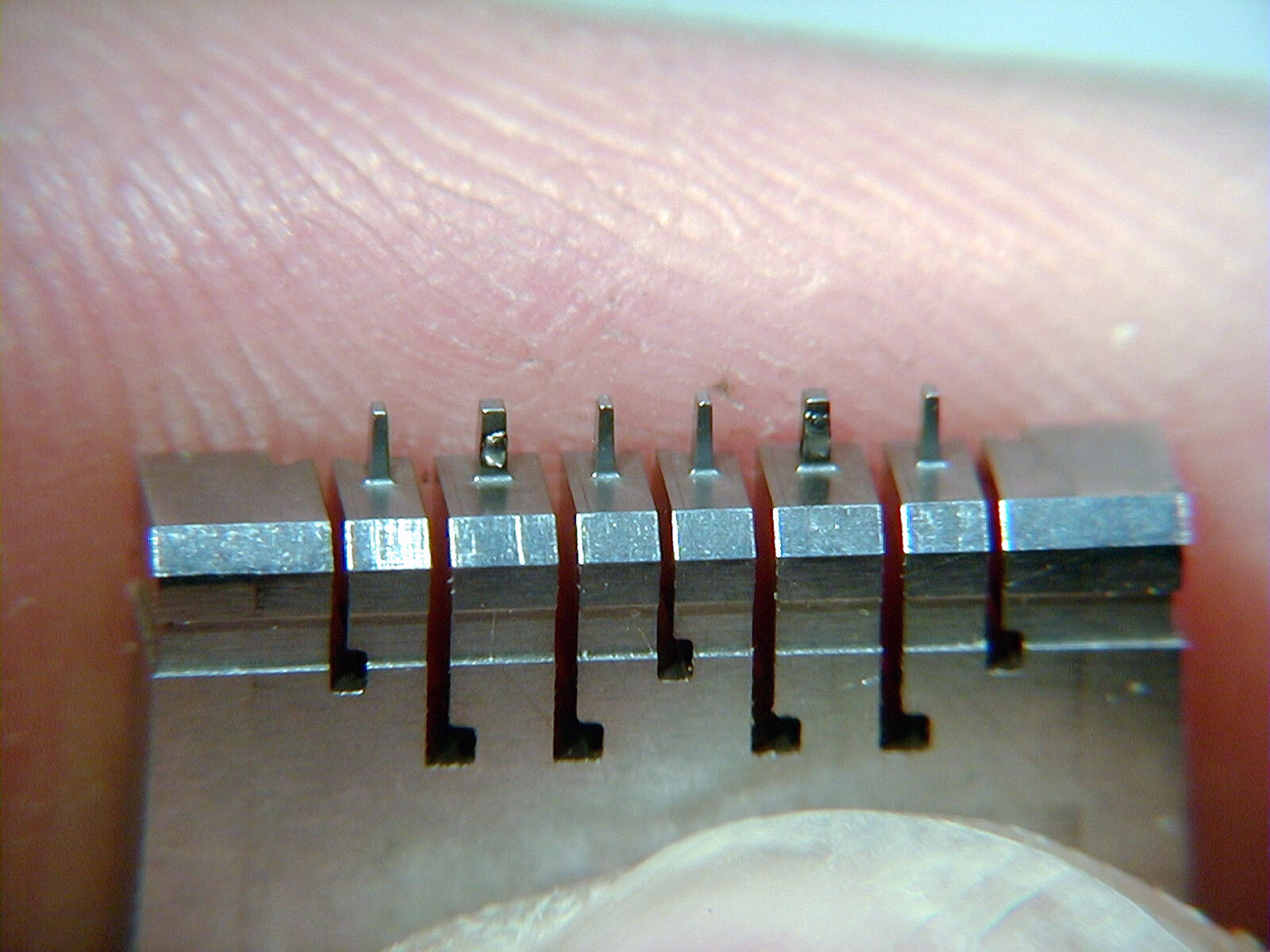

Precision welding for micro-scale, high-tolerance components.

ITAR-registered and compliant for sensitive applications.

Precision welding support for production, custom parts, and specialty assemblies.

Durable and precise welds for high-performance components.

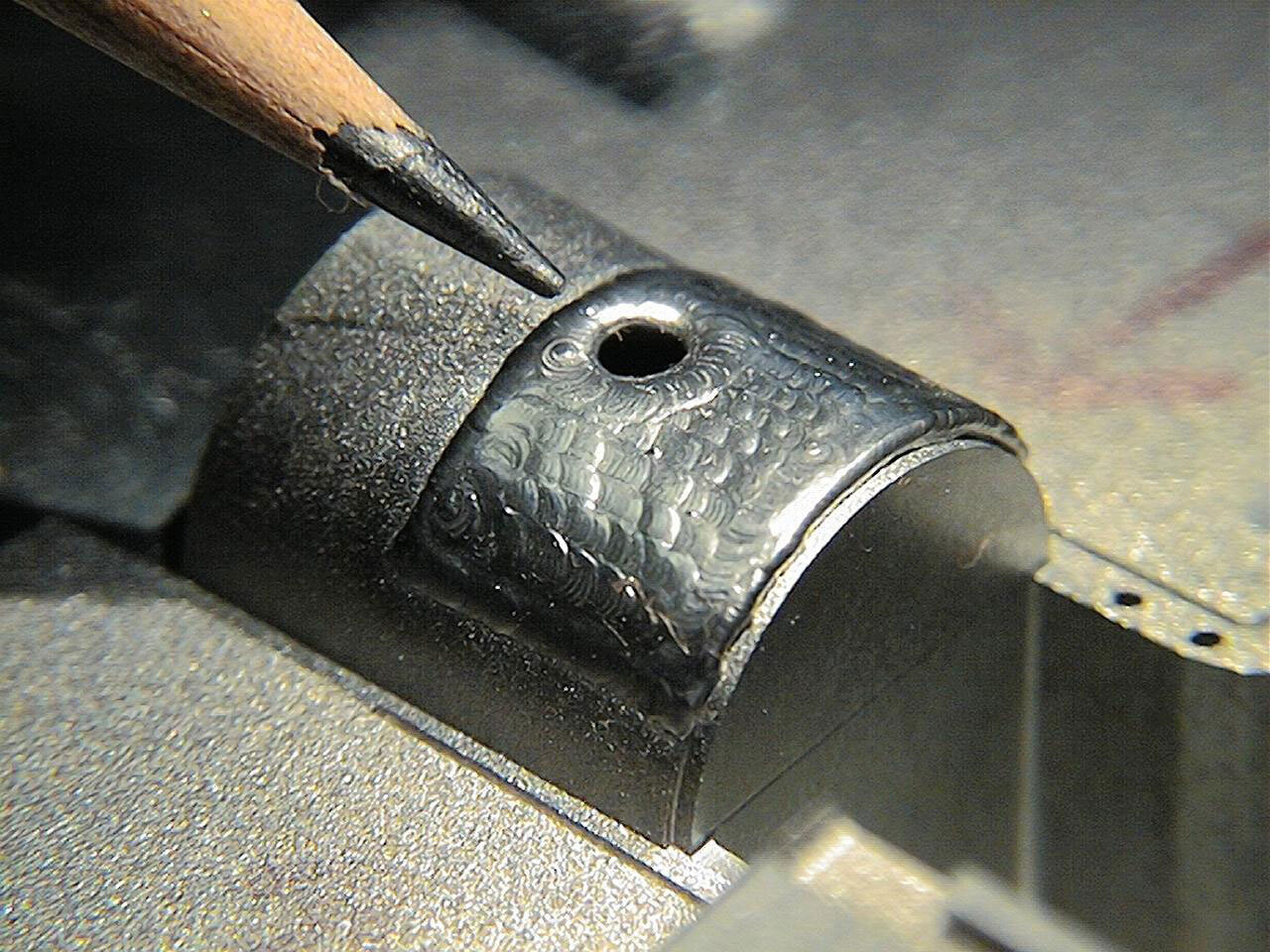

Complex shapes, repairs, and welds others won’t quote.

We specialize in cutting-edge solutions for all your project needs, from advanced & simple micro welding solutions to machining & fabrication and supply chain management for complex, high-precision parts other shops won’t touch. Tell us what you need — we’ll make it work.

Experience, precision, and personal service that deliver results for even the most demanding parts.

From micro TIG to advanced laser systems, our welding capabilities are built for accuracy and consistency. We handle small, intricate, and heat-sensitive components that require expert craftsmanship and engineering precision.

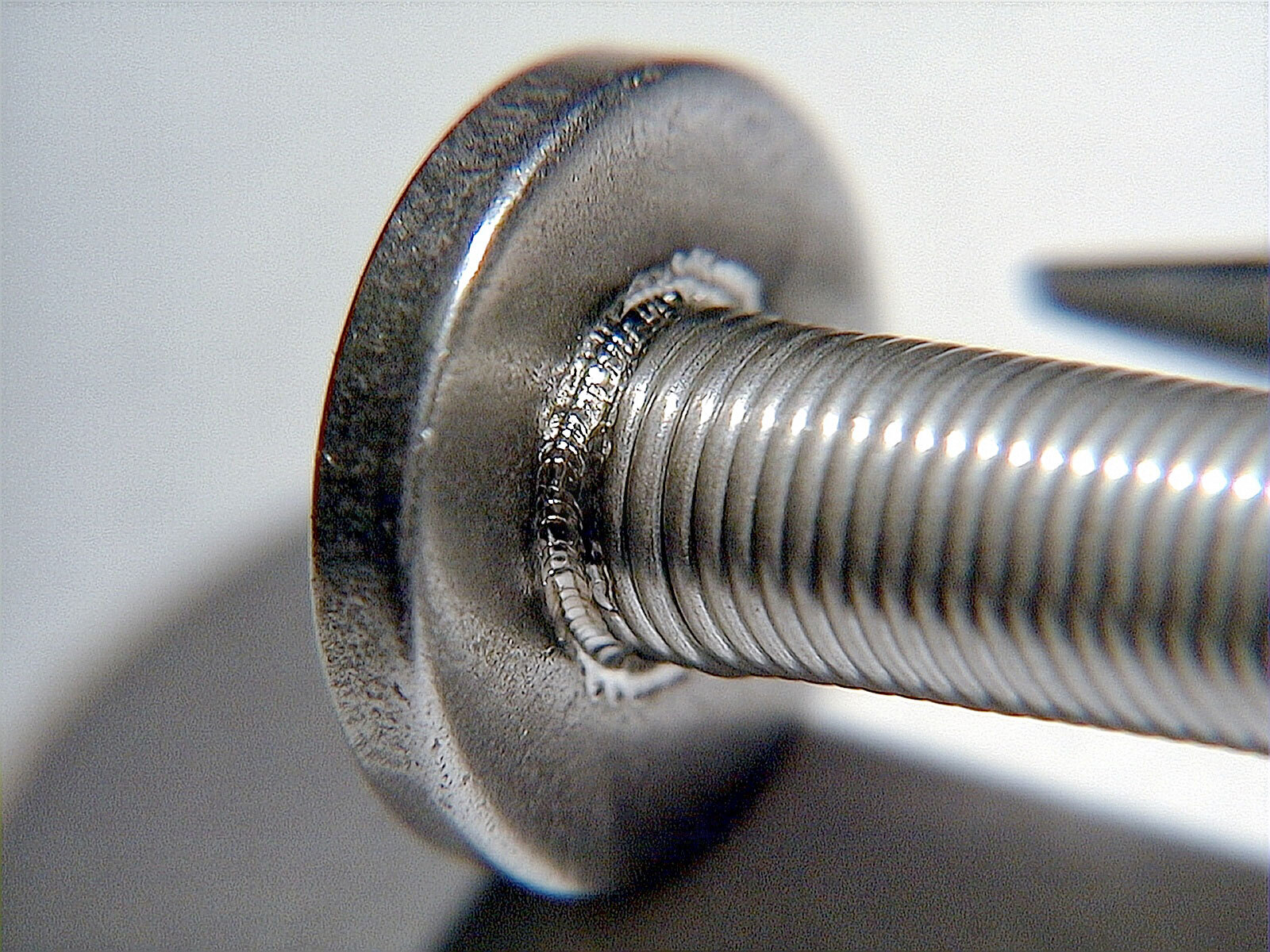

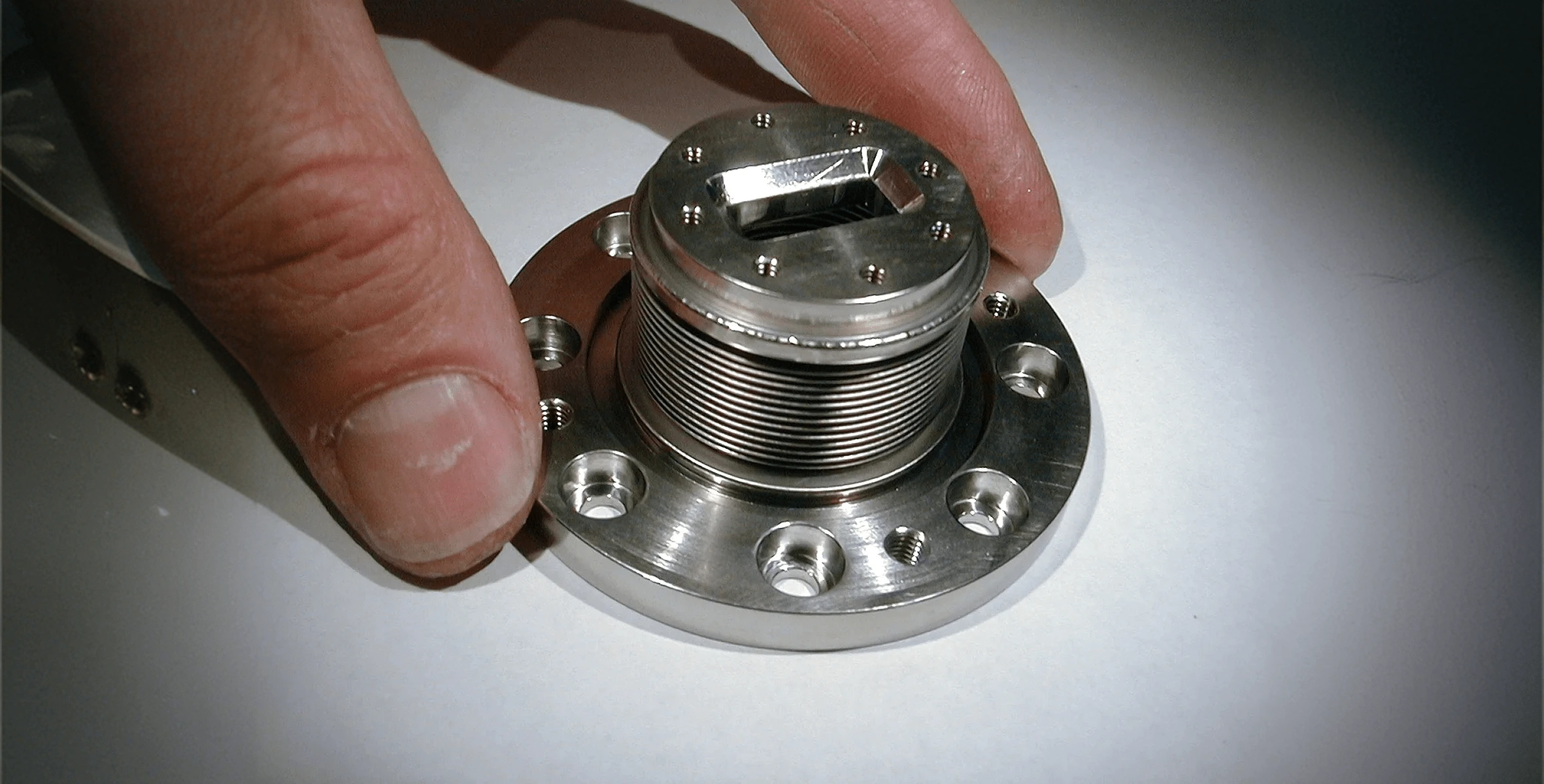

Our Class A micro welders deliver highly accurate welds on intricate shapes and tight-tolerance components—controlling heat, minimizing distortion, and ensuring clean results every time.

For applications requiring extreme accuracy and low heat input, our state-of-the-art laser welding systems produce precise, consistent welds ideal for delicate or heat-sensitive components.

Our micro TIG specialists create strong, accurate welds on small or challenging parts, delivering exceptional control, consistency, and minimal distortion—all with efficient turnaround times.

With extensive experience across multiple industries, we support production environments with fast, dependable welding services that meet your quality standards and delivery needs.

Need quick revisions or design changes? We help engineers bring ideas to life with flexible, hands-on prototype welding. Our day-to-day responsiveness keeps development moving and ideas flowing.

We specialize in micro welding solutions for complex, high-precision parts other shops won’t touch. Tell us what you need — we’ll make it work.

View real projects completed by our team, demonstrating the fine detail, precision, and skill that define Micro Arc Welding.

Posted onTrustindex verifies that the original source of the review is Google. Sick of the arogant jerks behind the counters at many gunshops, this place is a breath of fresh air! I recall my first gun purchase... what do you want? Not sure... Then, the eye rolling, oh no another newby!! Give me a break! Sorry to bother you! Lots of guns and ammo since then lost... sorry guys... Unless I'm in a hurry, I make the trip from Chelmsford to stock up. These people are friendly, knowledgeable, and they love what they do. My neighbor took me down a couple of years ago. We drove from Chelmsford. He went to school in Worcester and knows a number of the cops in town. They told him about the place when he had a problem with his deer rifle. I have gone many times since. Scott is the owner, this guy can do anything with metal... i think they have more gunsmith work than they can do, but they manage to get it done somehow. Its worth the wait. I've seen them do stuff others said couldn't be done. The same neighbor inherited a Colt Defender from his uncle. Nice, small, nickel plate finish. It had some nasty pitts on the handle and the barrel. It looked new when he got it back. They didn't plate it, they used a type of super hard finish, much tougher than plating and cheaper. He loves it! Anyway, great place, super people, good selection, fair prices. Nice job guys!!! Five stars!!! Ps. I agree with another post, dont judge them by their website...Posted onTrustindex verifies that the original source of the review is Google. Excellent Craftmanship and Excellent Customer Service - can not recommend anymore.Posted onTrustindex verifies that the original source of the review is Google. The staff at Pullman Arms are true experts in their field and have an impressive understanding of firearms and accessories. What really stood out to me was the genuine care that the staff demonstrated towards their customers. I am extremely pleased with my experience at Pullman Arms and highly recommend them to anyone looking for a reliable and trustworthy firearms store. Their exceptional service, knowledgeable staff, and customer-centric approach truly set them apart from the rest. Five stars all the way!Posted onTrustindex verifies that the original source of the review is Google. Fast and pleasant service!Posted onTrustindex verifies that the original source of the review is Google. Transfer went as smooth as you could ask for. Thank you so muchPosted onTrustindex verifies that the original source of the review is Google. Excellent! Prompt and curteous service, pleasure to do business with.Posted onTrustindex verifies that the original source of the review is Google. Five stars not only for getting a good deal on a consignment, transfers of other firearms in a very timely manner, and great service but above it all these guys stand firmly upright in support for the 2A sticking it to Bacon Hill and the current AG who is off her rocker.Posted onTrustindex verifies that the original source of the review is Google. I had an overwhelmingly positive experience at Pullman. My very first firearm purchase was here. I bought a Lee Enfield no4 mk1 longbranch. I used to work in the firearms industry. I had heard great things about their gunsmith. When I met him, I was stunned with how young he is with a reputation for quality work and experience as he has. I can personally vouch for this shop and the way they treat people.

Share your requirements and our experts will respond soon.